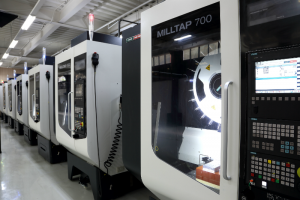

ALLJACK is the vanguard of mass production of parts for commercial and aerospace industry. Our engineers and designers create the specialized parts needed for today’s advanced aerospace components. Working closely with our customers, the ALLJACK team will design and construct parts using the finest materials and best design. Our decades of combined engineering and design experience, paired with the exceptional skill of our machinists and assembly team, reduces lead-time and eliminates unnecessary spending.

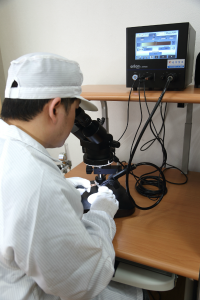

Our design and manufacturing processes maintain the demanding standards of the aerospace industry ensuring our products meet or exceed your expectations. We use only the highest quality aerospace-grade raw materials, only after they pass our rigorous incoming quality control inspections. We produce your parts only when the design meets your approval. Nothing leaves our factory without being inspected and tested many times over.