The rapid advancement of technology has created a high demand for fiber optic technology. Fiber optic connectors offer unmatched bandwidth and performance at a lower cost than other options. Fiber optic connectors have a wide array of uses for the drone and UAV markets and a seemingly endless list of commercial applications and consumer technology.

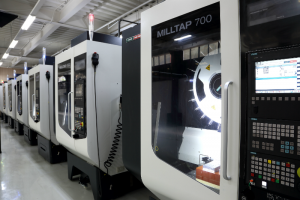

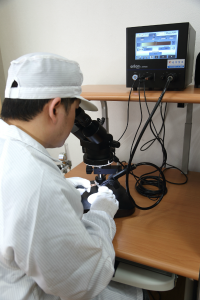

When looking for the right manufacturer to mass produce your fiber optic connector, you want someone who understands more than the basics. You need a partner who understands fiber optic applications, components, associated equipment, and design intricacies. Our design and research teams work hard to stay ahead of technological advances and developments. Our engineers study the various connectors on the market and their applications. Our machinists meticulously create the incredibly fine details needed for a superior connector. ALLJACK is your one-stop-shop for the design and mass production of fiber optic connectors.