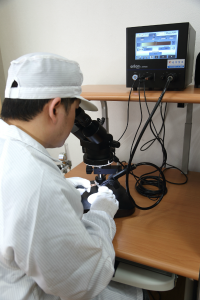

ALLJACK is on the leading edge for OEM mass production of parts and components for medical applications. Robotic and delicate medical instruments are utilized in a wide variety of surgical and medical procedures worldwide such as minimally invasive surgery, insulin pump and medical test equipment. Small, advanced medical tools and devices require the design and mass production of unique and intricate parts. Our engineers and designers can assist with part design and material selection. Our skilled CNC machinists have the training, experience, and intelligence required to understand and meticulously tool parts for the incredibly precise standards of the medical industry.

Surgical instruments have become so small and intricate that traditional methods of production are no longer able to create them with the level of precision required. At ALLJACK we use the absolute latest in manufacturing techniques and machinery to create small, thin, and complex designs with a shorter lead-time at a manageable cost. Our uncompromising quality control standards ensure that every manufactured part meets all industry standards, and yours.