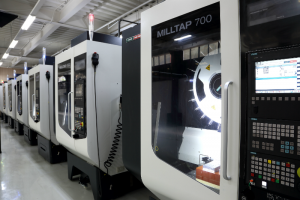

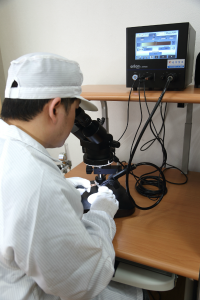

Commercial electronics have become integrated into our daily lives. New products are created and marketed at a staggering rate. When manufacturers need specialized parts and components for their electronic devices and equipment, they turn to ALLJACK: their one-stop-shop and partner in design and mass production. ALLJACK has been helping innovators design and produce small, intricate, and extremely-detailed parts and components since 1997. Our experience, equipment, and superior resources combine to create the superior ALLJACK advantage that makes us a leader in mass production.

The fast-paced, creative, and innovative electronics markets require a manufacturing partner who can understand your needs and applications. With ALLJACK you don’t have to worry about your design being lost in translation. The ALLJACK advantage means that your design team will see your project through the entire production process until it is packaged and ready to ship.