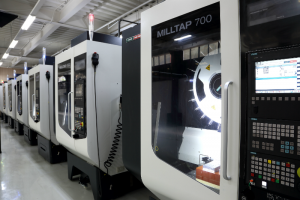

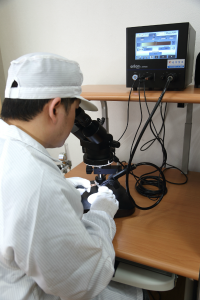

ALLJACK provides of a variety of prototyping services to verify precision and function before mass production. The ALLJACK advantage lies in our controlled production process, rigorous quality and cost controls, and our high maintenance standard.

The “A-Team” at ALLJACK can meet and overcome any design challenge, completing your prototype exactly to specification.