FAQs – Technical and Project related

We have been asked many technical and project related questions as follow which might assist you in understanding our service.

WHAT TYPES OF FILES DO YOU ACCEPT?

We’ve invested in new design and programming software. Therefore, now we can accept files format from PTC Creo V 2.0 as well as Mastercam Hypermill, Solidworks, and Catia.

WHAT ARE TYPICAL MATERIALS THAT ALLJACK MACHINES?

We are familiar with all variations of metal alloys and specialize in aluminum, Stainless Steel, carbon steel, titanium, iron, cast iron, brass, copper, plus a variety of industrial plastics.

WHAT TOLERANCES CAN YOU ACHIEVE?

Parts tolerance is different from project to project. There are several factors which might greatly affect the final tolerance: material choice, manufacturing processes, part size, wall thicknesses, design geometry, post-processing and the number, type, and size of features.

Our CNC machining standard tolerance is ±0.05mm ~ ±0.1mm, and precision tolerance can reach 0.005mm~0.05mm.

HOW DO YOU ENSURE YOUR QUALITY?

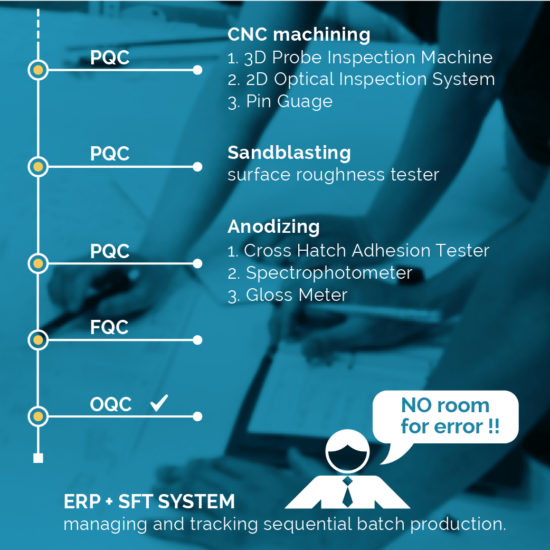

Our AS9100 certification recognizes that we are a company with an uncompromising commitment to quality. We’ve established comprehensive quality management and rigorous QC procedure: from initial design for manufacturing (DFM) review, IQC, FAI, QC, IPQC, PQC to OQC. Read more about our QC procedure and inspection equipment.

WHAT ARE TYPICAL LEAD TIMES?

Lead time can vary from several days to several weeks. It depends on the complexity of the project and any special technical inquiries involved. ( Lead times are quoted in working days not calendar days.)

DO YOU OFFER RUSH OR EXPEDITED DELIVERY ON ORDERS?

Depending on the complexity and our capacity, we work diligently with clients to support deadlines.

HOW DO I GET A QUOTE?

To get a quote for all of our services, email us alljack@www.alljack.com. We will fast reply your quote.

To accelerate our replying time, please let us know your inquiry detail, such as quantity, material, surface treatment, tolerance, lead time, etc., and providing your 2D design or 3D CAD files as well. After our experienced specialist’s review, our sales representative will discuss with you about potential manufacturing issues and provide our possible solutions.

HOW LONG DOES A QUOTATION TAKE?

In most cases, we respond within 2~5 days of receiving an RFQ.

HOW DOES ALLJACK COMPARE TO SUPPLIERS IN CHINA ON PRICE?

Our prices might be higher than Chinese suppliers. We know lowest cost is attractive as it may be, but sometimes the price is not the only reason you choose a manufacturing supplier. Quality and reliability are the keys. We invested in the most skilled workforce, and we use advanced imported equipment and high-quality materials to achieve ultimate quality standards. During the past twenty years, we have received enormous satisfaction from our clients, because we value our relationship with them. Our reputation is above all else, and we take action accordingly.

HOW ARE PARTS DELIVERED/SHIPPED?

We can deliver your orders globally in perfect condition and at the right price. We provide custom packaging and use secure and trusted courier services, and provide different global delivery support. We offer overnight express through DHL, FedEx, and UPS, but also shipping via sea by pallets or wood box.