The field of intelligent robotics is growing and expanding with increasing momentum. ALLJACK has the equipment and resources to be the forerunner of mass production for the small, specific, and highly-intricate parts needed for creating the latest in robotic technology. The highly inventive and competitive robotics industry creates a strong demand for new parts that can be designed and mass produced quickly and easily while keeping costs manageable.

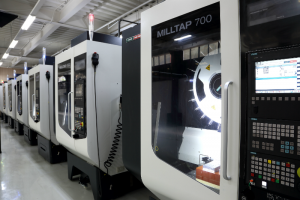

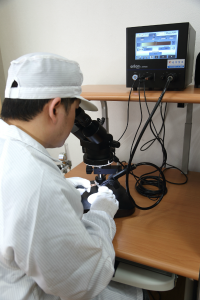

At ALLJACK we recruit the best designers, engineers, and machinists from around the world creating a dream team of unmatched skill and efficiency. Our teams receive regular, ongoing training to stay current on mass production innovation and new developments in the field of robotics. We provide raw material COA to guarantee its composition and use DMG MORI 5-Axis CNC and Turn-Mill Machines with surface finishes techniques such as heat treatment to produce the incredibly detailed parts necessary for your project. Our goal is to reduce the manufacturing cost and help your designs become mainstream products in the market.

The list of applications for robotic technology continues to grow. Some of the more popular current applications for intelligent robotics parts are:

- Medical Robot-Assisted Surgery

- Robotic modules and components for space vehicles

- Consumer Robotics

- Production Line Industrial Robotics

- And More!