Injection Molding and Die Casting

Our decades of experience in prototyping and mass production have made us experts in the different casting and molding processes. At ALLJACK we have the equipment, technology, and the superior training necessary to deliver a product second-to-none. We offer a variety of casting and molding options to suit your production needs.

Modling & Casting Options

Vacuum Casting

During vacuum casting, polyurethane material is poured into a vacuum mold to create exact replicas of an original model. Metal and plastic materials can both be used in vacuum casting. Vacuum casting is extensively used in mass production for reducing cost and lead time. Vacuum casting is ideal for customers seeking unique finishes, textures, materials, and other features in their prototypes.

Injection Molding

Injection molding uses thermoplastic and thermosetting materials, injecting them into a mold to produce solid parts. Injection molding is widely applicable, used to create small components and entire vehicle or aircraft frames.

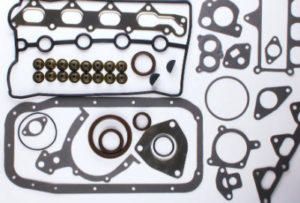

Silicone Rubber Molding

Liquid material is poured into a mold, then solidified using temperature and pressure to create custom silcone OEM parts for the automotive, medical, and food industries. Silcone rubber molding is typically used for the mass production of seals, gaskets, valves, and cables. Parts made using silicone rubber molding have excellent thermal, chemical, and electrical resistance. Silicone rubber molding is ideal for parts that have to withstand extreme temperatures and sterilization.

Die Casting

Die casting uses high levels of pressure to force metal into a mold cavity created using steel dies. The dies are made from hardened steel machined into a shape, similar to a polymer injection mold. Using non-ferrous metals such as Zinc, Copper, Aluminum, Magnesium, Lead, Pewter, and other alloys, die casting enables increased production, dimensional accuracy and consistency, small-scale processing, excellent surface finish, high-strength, and the casting of thin-walled parts.

OUR PROCESS

Selection of Raw Materials

A finished product is only as good its beginning. Our engineers have decades of experience designing and creating unique concepts. They work closely with our customers to determine the proper materials required to produce your design. All raw materials used at ALLJACK undergo a rigorous incoming QC inspection ensuring that the finished item is flawless and functional.

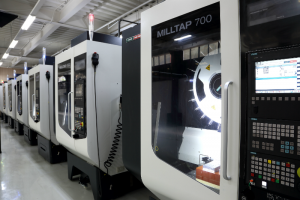

Manufacturing

We recruit the best CNC machinists from around the world and provide them with continuous training. Our specialists input design data into our computer system with extreme attention to detail. Using the latest DMG MORI CNC machines our machinists apply the correct operations, tools, and equipment necessary to ensure absolute accuracy.

Post-Processing

Once your design has been manufactured to the exact specifications, components undergo surface treatments to achieve their desired visual and functional effects. We offer a wide range of colorization options which, if selected, will be applied during this stage. Components are assembled if necessary and checked for proper function

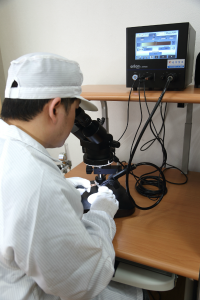

Inspection and QC

At ALLJACK we offer the absolute highest levels of quality control. Our inspection teams verify the quality and functionality of your project using a host of instruments. Prior to shipping all projects undergo intense quality control inspections ensuring project accuracy and customer satisfaction. Products are inspected to ensure they meet any and all required industry standards, and the finished product best represents the original design in its entirety.

Packing and Shipping

A perfect product is of no use if it is damaged during shipping. All finished materials are packaged carefully by a dedicated department to ensure delivery in perfect condition. At ALLJACK we use trustworthy and reliable international carriers to deliver our completed work, leaving no room for error.