-

-

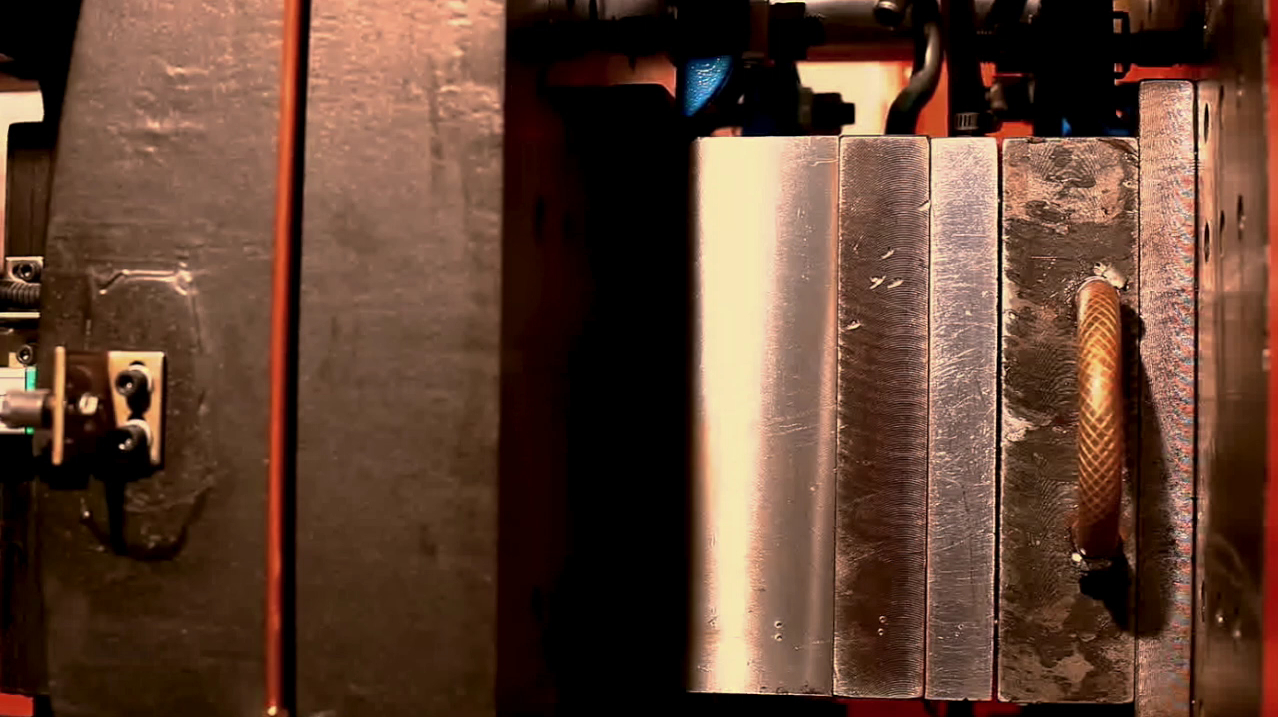

PRECISION.

PRECISION.

SERVICE.

SCALE.We are a Taipei, Taiwan - based manufacturer of high-quality precision parts for global companies who require speed, accuracy, and attentive personal service. -

Making Your IdeasREALITYNeed high quality manufacturing at a price that makes sense?See What ALLJACK Can Do For You

Making Your IdeasREALITYNeed high quality manufacturing at a price that makes sense?See What ALLJACK Can Do For You

That's what we do for our clients every day. -

IF YOU CAN DREAM IT

IF YOU CAN DREAM IT

WE CAN CREATE IT.ALLJACK has the experience, knowledge, and technical abilities to be your 1-stop shop for manufacturing in Taiwan. -

RelentlessPURSUIT OF PERFECTIONWe are passionately committed to the goal of creating the highest quality parts at the best price, delivered with personal, attentive service.

RelentlessPURSUIT OF PERFECTIONWe are passionately committed to the goal of creating the highest quality parts at the best price, delivered with personal, attentive service. -

MANUFACTURING

MANUFACTURING

THAT SCALES WITH

YOUR BUSINESS.High quality manufacturing for your projects regardless of size.GET A QUOTE ON YOUR PROJECT